Disambiguation: This article is about the synthetic alloy erudium. This subject is not to be confused with the superheavy element erudium (transuranic element) from which its common name is derived. See Annals of Chemical Synthesis Q1 9 CY pp. 206 and Moretta et. al. 167 PTC.

—

The most coveted material in power systems engineering is erudium, a room-temperature superconductor. In everyday parlance, erudium is a synthetic alloy made of a noble metal such as platinum laced with trace amounts of the weakly radioactive transuranic element erudium-354, from which it bears its name. It is the crucial constituent of coils manufactured for contemporary erudium-based superconducting magnetic energy storage (ESMES).

In 167 PTC, Dr. Luis Moretta and his team of chemists at the Republic University of Kolaris East Branch synthesized the first and perhaps only quasi-stable superheavy element on the periodic table’s so-called Island of Stability. They named this element erudium, after the root word for “learned knowledge.” It is a superactinide and has 126 protons and 228 neutrons, for a total of 354 nucleons. In the course of their research, they found it has an impressive half-life of over 9,000 years and chemical properties similar to thorium with several positive oxidation states.

The real breakthrough came years later in 144 PTC, when Novani metallurgists back on Maridea demonstrated the phenomenon of superconductivity in several erudium-laced alloys at temperatures of up to 357 K. Somewhat confusingly, the news media and ergo the Novani public referred to these new alloys collectively as erudium. The promises of harnessing such a civilization-changing wonder material meant that semantics would be disregarded by the public at large.

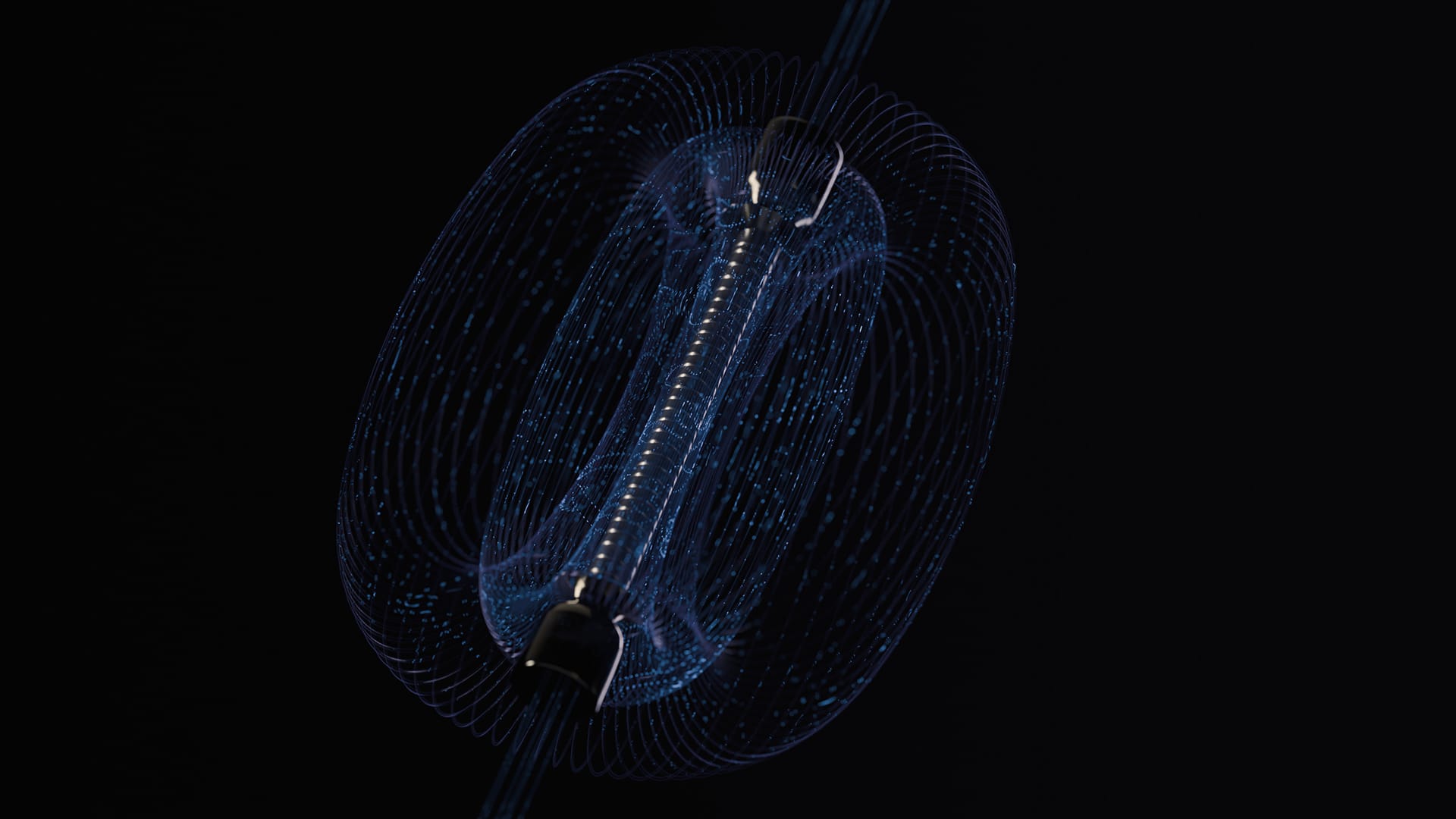

Erudium is now the foundation of z-pinch fusion reactors. A z-pinch reactor crunches and confines plasma across the long axis of a cylindrically shaped fusion chamber. When an electric current runs through the plasma down the centerline, the electromagnetic force will pull the plasma ions towards each other. The gas pressure of the plasma and the electrostatic force attempt to counteract the pull. But if the crunch provided by the jolt of current is sufficient, the plasma undergoes thermonuclear fusion, releasing net energy. Erudium provides the capacitance necessary for such an extreme discharge.

Direct current is passed through an erudium coil to generate a static electromagnetic field. The superconducting nature of the coil provides for field stability with negligible (even zero) energy loss. DC will continue to loop indefinitely even when the coil is magnetically saturated. End-to-end efficiencies of ESMES exceed 98%, and some intricately designed systems close in on 100%. The field energy can be discharged rapidly at the picosecond scale, which is necessary for the fusion ignition process.

As a superb inductor, erudium is also used in many military applications where quick energy dissipation and high efficiency are needed: mass drivers, ion beam steering, power banking for certain small arms, etc. In civilian use, it is applied in power grid management, emergency energy storage, maglev trains, and so on.

Just as with any superconducting material, erudium has a normal or resistive state at a high enough temperature: heat that is often experienced during forging and manufacture or near an active fusion reactor. Environmental heating can cause a magnet quench, as can material defects in the superconducting coil. Erudium fabrication is complicated by the necessity for strict material purity. Great care must be taken to prevent field normalization, which can have some disastrous consequences at scale.

Above the critical field limit, the superconducting state of erudium is destroyed. This means there is a maximum charging rate for an erudium inductor per unit volume, given that the magnitude of the electromagnetic field determines the flux captured by the superconducting coil.

For microfusion applications whereby the volume of reactor plasma is small, miniaturized solenoids are used. This has the helpful effect of reducing material costs, as erudium requires careful fabrication and spooling. For gigawatt-scale reactors that require larger volumes of plasma to be ignited, suspensions are placed around heavier toroidal coils in order to mitigate induced electromotive forces.

Erudium undergoes alpha decay and has many of the same biohazards as thorium. Although alpha particles cannot penetrate skin, erudium is a carcinogen largely because of the daughter products its decay produces. These products are more dangerous and increase the alloy’s safety hazard with its age. The amount of erudium-354 present in standard alloys is less than 1%, and governments Bary-wide place an upper limit on E-354 content for safety. Standard handling protocols for low-level radioactivity are appropriate.

Because so little elemental erudium is used in the alloy and because of the increasing safety hazard posed by its daughter products, ESMES systems lose both efficiency and usefulness over decades and must be periodically replaced. Besides standard biological shielding, mu-metals, supermalloys, and other structures shield sensitive electrical components from powerful ESMES systems.